NEWS

2025-12-02

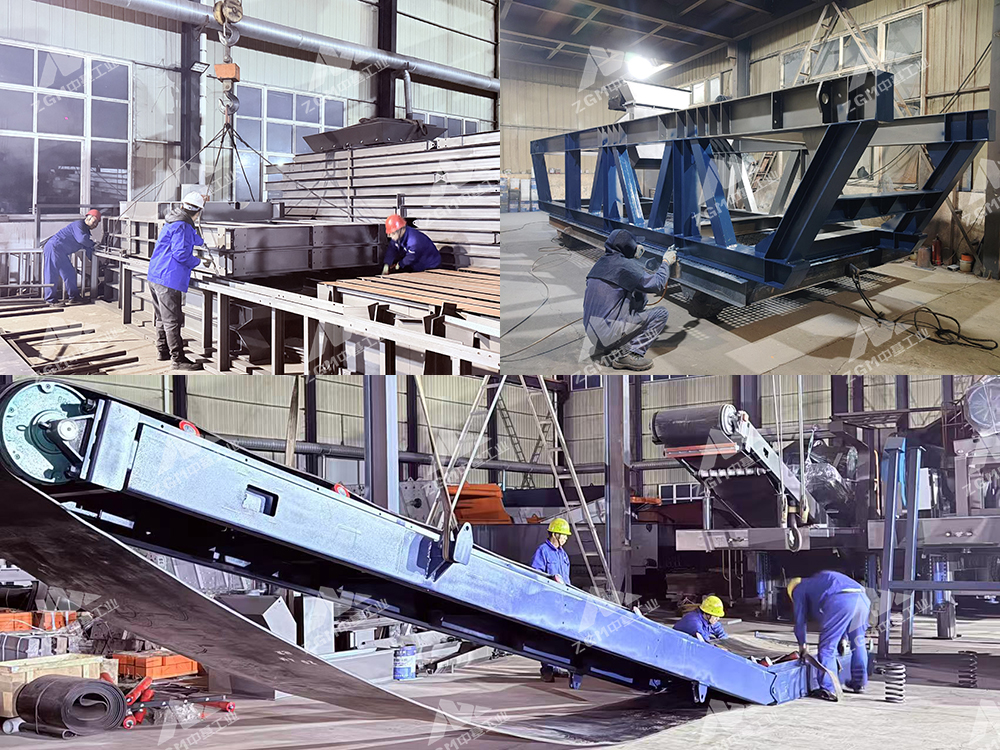

In the modern production workshop of ZGM, another batch of frame crushing equipment has completed debugging and is ready for dispatch, soon to head to the next project site. As a benchmark enterprise in China's mining machinery field, ZGM has always focused on equipment manufacturing and technological upgrades for aggregates, mining, industrial powder, and construction waste treatment. Addressing industry pain points such as complex equipment infrastructure construction, difficult site relocation, and long installation cycles in traditional crushing production lines, ZGM drives innovation through technology to provide customers with more efficient and economical crushing solutions – frame crushing equipment.

The birth of frame crushing equipment represents a thorough innovation in traditional crushing production methods. Through an integrated, modular design concept, it combines feeding, crushing, conveying, and screening systems onto a sturdy heavy-duty steel structure base. The equipment undergoes full system integration and debugging before leaving the factory, achieving high compatibility from core hosts to auxiliary components. There is no need for on-site concrete foundation pouring; only simple hoisting and positioning are required for rapid production.

Integrated Heavy-Duty Steel Structure Frame: A Rock-Solid "Foundation"

Strong Integrity and Stability: Unlike traditional equipment that requires separate foundation laying and on-site assembly, frame crushing equipment integrates the host, motor, conveying system, and more onto a robust heavy-duty steel structure base. This integrated design fundamentally eliminates the risks of displacement or settlement caused by prolonged vibration, providing a rock-solid operational foundation for continuous high-intensity work.

Fatigue and Deformation Resistance: Made from high-quality, thickened steel frames with high rigidity and fatigue strength, it effectively withstands significant impact loads during production. This ensures that core components maintain precise alignment during years of operation, extending the equipment's lifespan.

Modular Design Grants Unparalleled "Flexibility"

Rapid Deployment, Cost Savings: The frame structure achieves a high degree of modularity. Most debugging is completed before the equipment leaves the factory. Upon arrival at the site, only simple hoisting and interface connections are needed to start production, shortening installation and debugging cycles and saving significant labor, time, and infrastructure costs.

Easy Relocation, High Mobility: For projects requiring frequent site changes (such as multiple road constructions or regional mining operations), the frame crushing station can be relocated as a whole or in modules, truly achieving "ready upon call, operational upon arrival."

High-Efficiency Crushing Performance: Guarantee of Output and Quality

Optimized Chamber Design, Outstanding Output: The crushing equipment features an optimized chamber design validated through countless computer simulations and practical applications. This ensures laminated crushing of materials within the chamber, not only effectively enhancing processing capacity but also significantly increasing the cubic content of the finished product, resulting in better particle shape.

Powerful and Energy-Efficient: Equipped with high-power, high-efficiency motor drive systems, it ensures strong crushing force while reducing energy loss through advanced transmission design, achieving high efficiency and energy savings. The enclosed design, paired with a comprehensive dust removal system, easily meets environmental requirements.

Intelligent Control and Maintenance Convenience

Centralized Control, Easy Operation: Key parameters of the entire crushing station are integrated into an intelligent control system, enabling one-button start/stop, fault alarms, and remote monitoring. This greatly reduces the labor intensity for operators and dependence on proficiency.

Clear Maintenance Access, Safe and Worry-Free: The frame structure fully considers maintenance needs during the design phase, reserving spacious and safe inspection spaces and walkways. This makes daily inspections, replacement of wear parts, and other tasks easy and safe, effectively reducing downtime.

Wide Range of Application Scenarios: Whether it's hard basalt, granite, or complex construction waste, our frame crushing equipment can handle it with ease.

Large-scale sand and aggregate production lines: Serving as the core host for secondary or fine crushing, providing stable, high-quality parent rock.

Open-pit mining: Directly entering mining areas to achieve efficient, continuous crushing operations.

Engineering construction and road projects: Providing a continuous supply of high-quality aggregates for project sites.

Construction waste recycling: Turning waste into treasure, becoming a "scavenger" for urban green development.

From design to finished product, from technological innovation to service upgrades, we always prioritize customer needs and rely on craftsmanship to provide more efficient, stable, and reliable crushing solutions for infrastructure, mining, building materials, and other industries. In the future, ZGM will continue to increase R&D investment, break through more technological bottlenecks, and launch more efficient, intelligent, and environmentally friendly crushing equipment, striving to become a "global leading crushing solution service provider."

Copyright © 2024 Henan ZGM Industrial Technology Co.,Ltd

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN